Cost effective Continous Casting

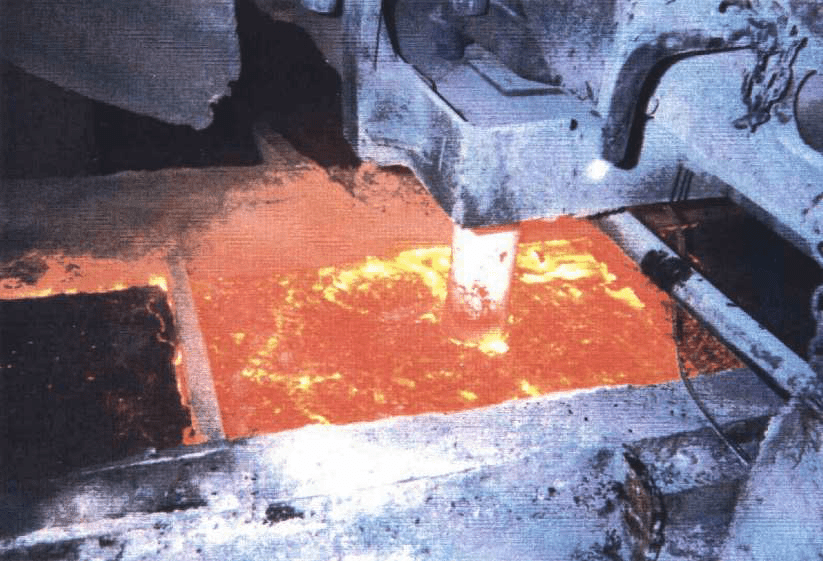

Continuous casting requires exceptional refractories in order to successfully carry out its mission. SQ Insertec manufactures and distributes a multitude of refractory products for the different types of continuous casting that exist.

Tundish lining -TUNSIL

Tundish lining – TUNMAG

Sealing Cement – SIDERCOL

Tundish Cover – MOLDCOAT

Starting Devices – ALUVAC

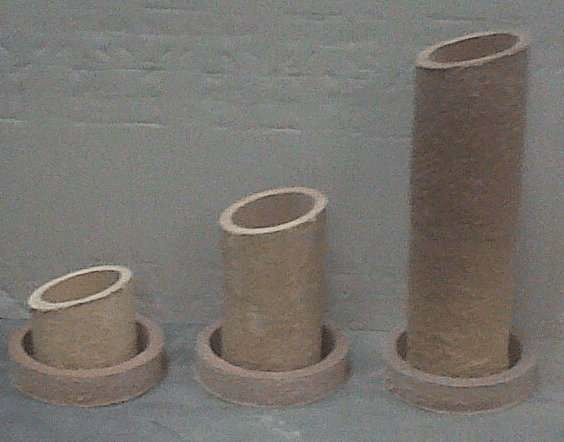

Before teeming, the stopper rods and tundish nozzles have to be well preheated to avoid freezing when the teeming starts.