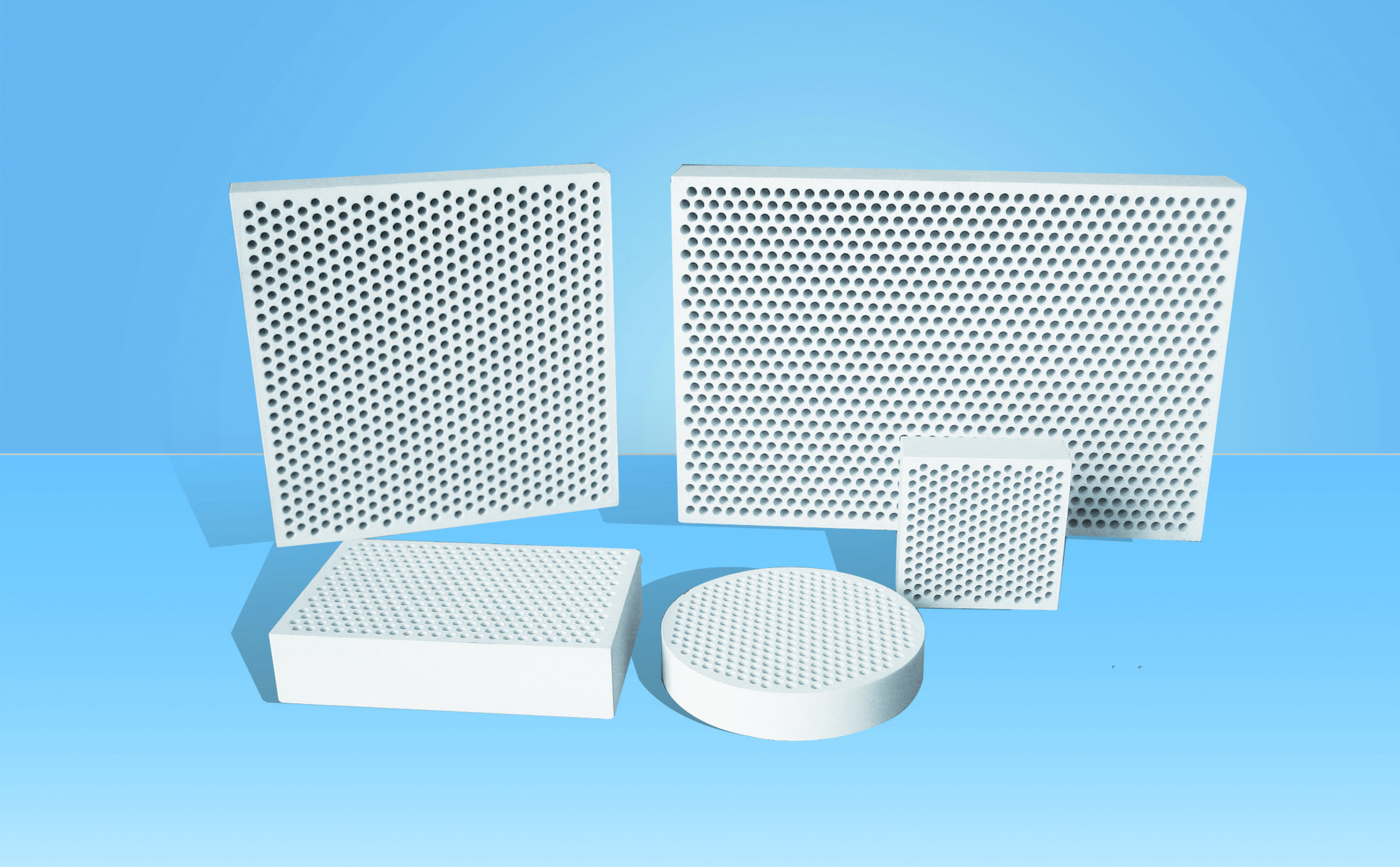

SIC foam, Zirconia, Alumina, Carbon and pressed filters for steel and foundry

FCF-1Z Zirconia foam ceramic filters

Utilization

Stainless steel, carbon steel and large iron castings metal liquid filtration.

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

| Type | Operating temperature <= (ºC) | Application Scope |

|---|---|---|

| FCF-1Z | 1700 | sand casting |

| FCF-1ZR | 1750 | investment casting |

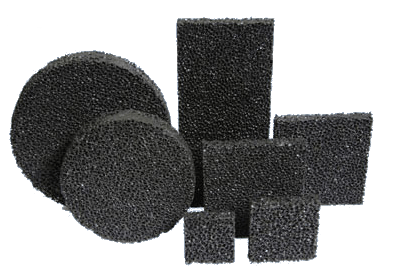

FCF-1S Black foam ceramic filters for steel casting

| Type | Operating temperature <= (ºC) | Application Scope |

|---|---|---|

| FCF-1S-10 | 1650 | big iron castings |

| FCF-1S-20 | 1700 | carbon steel, low alloy steel |

| FCF-1S-Mn | 1650 | high manganese steel |

Utilization

Carbon steel, low alloy steel, high manganese steel, big iron castings metal liquid.

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

FCF-2 Foam Ceramic Filters

Utilization

Ductile iron, grey iron and nonferrous castings metal liquid.

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

| Type | Operating temperature <= (ºC) | Application Scope |

|---|---|---|

| FCF-2 | 1500 | grey iron, ductile iron, nonferrous castings |

| FCF-2D | 1460 | Iron castings |

FCF-3 foam ceramic filters for aluminium castings

| Type | Operating temperature <= (ºC) | Application Scope |

|---|---|---|

| FCF-3 | 1200 | aluminium castings |

| FCF-3B | 1300 | big aluminium castings |

Utilization

Aluminium castings

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

FCF-4 foam ceramic casthouse for aluminium castings

Utilization

The filtration of Alumnium Metal Stream.

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

| Density | Porosity | Compression strengh MPs | PPI |

|---|---|---|---|

| 0.36-0.45g/cm3 | 80-90% | > 1.0Mpa | 10-90 |

FCF-5 graphite ceramic foam filters

| Density | Porosity | Compression strengh MPs |

|---|---|---|

| 0.36-0.45g/cm3 | 80-90% | > 1.0Mpa |

Utilization

Aluminium castings

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

FCF-M Foam Ceramic Filters For Magnesium Alloy

Utilization

Magnesium alloy.

Features

| Type | Operating Temp >= (ºC) | Application Scope |

|---|---|---|

| FCF-M | 1150 | Magnesium alloy |

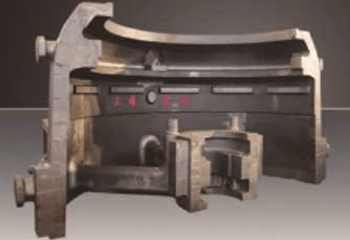

JC100 Integrated filter section

| Type | Reference flow rate | inlet (outlet) size | Application Scope |

|---|---|---|---|

| Y125/22-Z-10 | 18kg/s | c 50 | Stainless steel / Carbon steel |

| Y125/22-S-10 | 9.8kg/s | c 50 | Carbon steel |

| F150/22-Z-10 | 33kg/s | c 60 | Stainless steel / Carbon steel |

| F150/22-S-10 | 18kg/s | c 60 | Carbon steel |

Utilization

The product is suitable for the filtration and purification of large and medium size engineering machinery, valves, rail transit and other steel castings.

Features

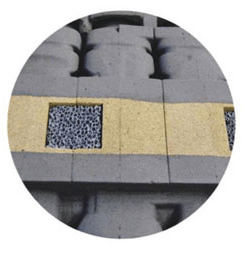

CHF Pressed Ceramic Filters

Utilization

Iron castings and non-ferrous castings.

Features

Storage and Shelf life

Keep in cold and dry place, away from moisture, avoid stacking and compression. Shelf life: 1000 days

| Type | Operating temperature <= (ºC) | Application Scope |

|---|---|---|

| CHF-2 | 1500 | Iron, cooper, aluminum castings |

Filter Cloth

| Type | Operating Temp <= (ºC) | Mesh size | Application Scope |

|---|---|---|---|

| BXF-1 | 1450 | 1.5*1.5/2.0*2.0/2.5*2.5 | Cast iron |

| BXF-2 | 850 | 1.5*1.5 | Cast non-ferrous |

| BXF-3 | 1560 | 2.0*2.0/2.5*2.5 | Small-medium cast steel |

Utilization

Small and middle castings.