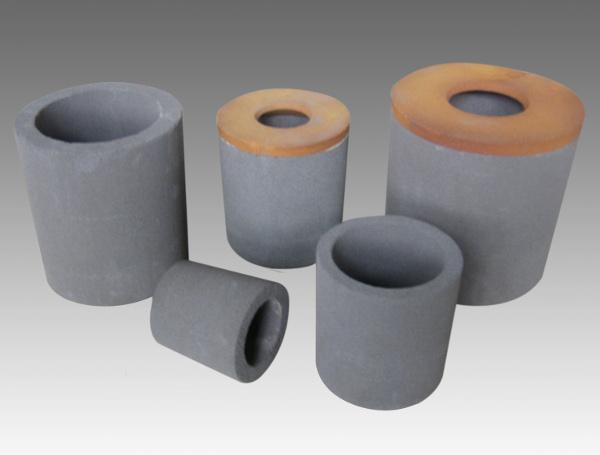

Slurry and Core-shot Sleeves for steel and foundry

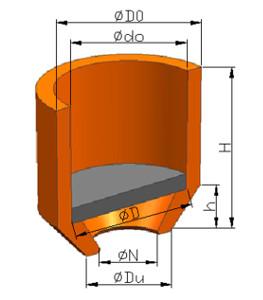

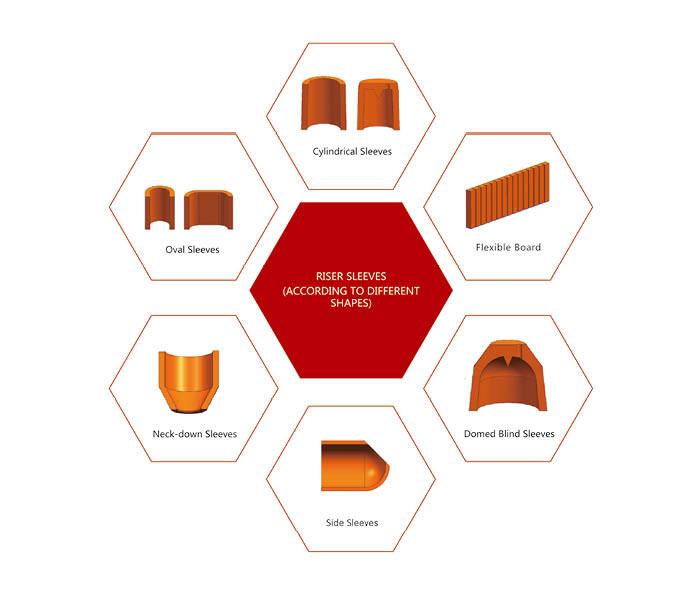

Slurry sleeves

FT 500 series slurry sleeves

Highly insulating and exothermic feeder sleeve for iron and steel castings.

| Type | FT500modulus(cm) | Geomodulus(cm) |

|---|---|---|

| M40x75~M140x170 | 1.35~3.94 | 0.87~2.8 |

| A30/90~A140/170 | 0.9~3.73 | 0.64~2.5 |

| A50/60R~A130/140R | 1.41~3.69 | 1.0~2.64 |

| S70~S140 | 0.89~3.68 | 0.63~2.64 |

| T40/60/60~TT100/150/150 | 1.29~3.33 | 0.94~2.38 |

| Lid accompany with sleeves | ||

FT100 series insulating and exothermic sleeves

| Type | FT100modulus(cm) | Geomodulus(cm) |

|---|---|---|

| M150x150~M325x325 | 3.5~8 | 2.7~6 |

| T100/200~T360/580/300 | 3.9~10 | 2.7~7.2 |

| S15~5300 | 3.5~7.5 | 2.9~6 |

| X150~X350 | 4.2~7.5 | 3.4~6 |

| Corresponding lids | ||

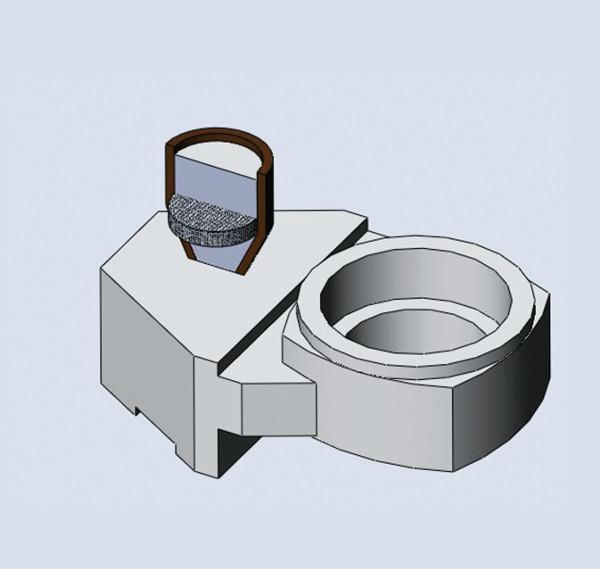

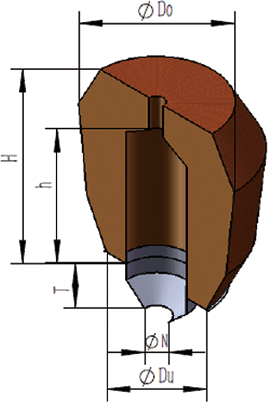

Core-shot sleeves

FM series core-shot sleeves for iron and steel castings

| Type | FM100modulus(cm) | Geomodulus(cm) |

|---|---|---|

| FM100~A120/35~A140/170 | 0.5~3.8 | 0.3~2.5 |

| FM100~M140x75~M140x170 | 1.3~4.1 | 0.7~2.5 |