Cost effective Steel Ingot

The casting process in molds requires the best refractory and auxiliary materials possible for the perfect execution of it. SQ Insertec manufactures and distributes a multitude of refractory products for casting in steel ingots.

Hot Top

Hot top – ISOINGOT

Thanks for its insulation performance, Hot Top products avoid shrinkage and offer good ingot directional solidification.

Hot top – ISOINGOT L

Thanks for its insulation performance, Hot Top products avoid shrinkage and offer good ingot directional solidification.

Hot top – EXOINGOT

Thanks for its insulation performance, Hot Top products avoid shrinkage and offer good ingot directional solidification.

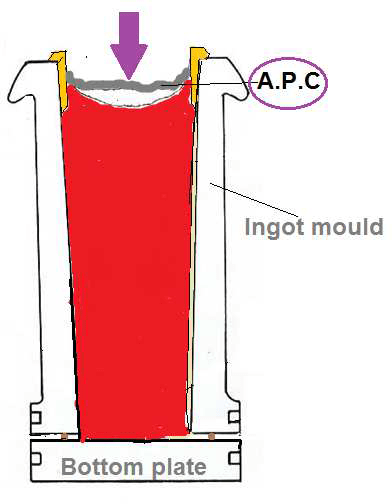

Anti Piping Compound

INGOTERM LE-EX

Avoid the heat lost from the top surface of the ingot, therefore it avoid shrinkage and provide a good sound ingot.

EXOTOP

Pre-shaped, avoid the heat lost from the top surface of the ingot, therefore it avoid shrinkage and provide a good sound ingot.

Teeming fluxes

Sealing device – INGOBOT

The preshaped device is set between the mould and the bottom plate to prevent finning and steel break out (leakage) during teeming.